Special Purpose Machines

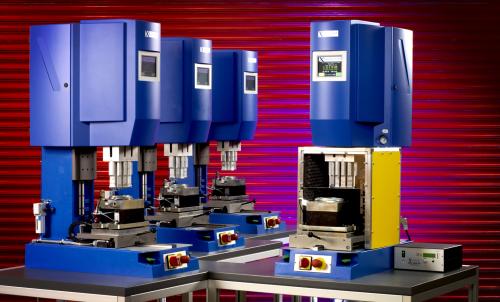

Xfurth has an outstanding reputation for design, build quality, reliability and functionality of our special purpose machines. We are a company run by expert engineers who have the extensive knowledge it requires to design and build machines to exacting standards.

We believe it is imperative to build a relationship with you, our client, and work closely with you so we can fully understand and help you with your design criteria and component specification. With our flexible approach and our combined knowledge we are able to design and build purpose machines, which will meet and exceed your expectations.

Maybe you have no specific criteria. In which case, we can still help you, and you can be confident in our reputation that our engineers will design and build your special purpose machine.

Or, perhaps you have a preferred machine builder. Xfurth can work with them too. Because we are engineers, we can advise your machine builder on the integration of the ultrasonic or spin welding equipment to provide you the best solution. We are more than happy to supply our ultrasonic equipment as stand-alone systems if this service is required.

Please contact us on 01582 436000 for more information.

Six head 35 kHz ultrasonic staking machine for attaching door pull to rear door panel for an automotive application.

Three head 40 kHz ultrasonic staking machine for the attaching of label badge to internal trim panel for an automotive application.

Three head 40kHz ultrasonic staking machine for the assembly of under seat tray for an automotive application.

Servo spin welding machine with sliding table for an automotive application.

Single head 20kHz ultrasonic welding machine with composite tooling for welding a blister pack.

Two head 20kHz ultrasonic welding machine, first head for welding a filter membrane into a moulded parts. The second head to weld the two filter body halves for a medical application.

Servo spin welding machine with programmable nest clamp platen to accommodate various lengths of extruded pipe between 84mm to 480mm and tooling to accommodate extruded pipe diameters 10, 15, 25 & 40.

Single head 20khz ultrasonic welding machine with two position sliding table for building product.

Four & Three Head 20kHz Ultrasonic Welding Machine with Side Clamping and Part Ejection for Assembly of Mybuddy Box foldable box.

Five head 35Khz Continuous ultrasonic welder for seal two layer of filter material for a medical application.

Standard machines with composite tooling for ultrasonic welding an air care product.

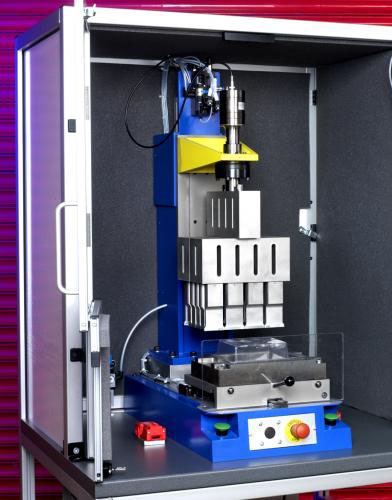

Ultrasonic Machine Refurbishment with Acoustic Cabinet