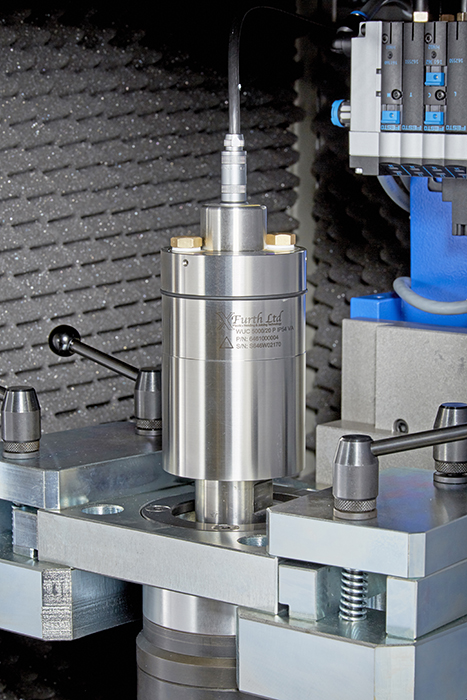

Our ultrasonic machines have been developed over the years through our extensive and professional experience incorporating a group of features to give you a high degree of reliability, stability and ease of use.

Key Points:

- Frequency Range: 20kHz – 40kHz

- Power Range: 400W – 4000W

- Pneumatic Cylinder Range: Ø40 – Ø80mm

- 'H' frame aluminium casting construction

- Rigid dovetail head assembly

- Touch screen control interface

- Facility to weld and monitor in time, distance, power and energy

- 99 Program memory

- Printout capability of all set parameters or storage of all welded data to PC or network

- Option of rocking table (levelling) or sliding table

- Standard Options: Linear Encoder, Part Sensing and Part Ejection, Proportional Valves – (more accurate control

of pressure, digitally set via HMI), Facility to monitor all available parameters during the weld cycle, Ability to weld using collapse distance

- Easily adapted to suit automated lines

- British built and design

- Depending on the application, all of our machines can be adapted to suit the majority of customers requirements

Ultrasonic welding machines can be used for various functions such as component welding, spot- welding, riveting, swaging, inserting and de-gating mouldings.

Please contact us on +44 (0) 1582 436 000 for more information.

Further Information

For more information, download our XUM Press Brochure.